Olympic Geomembrane Installation with Simon Machinery (China) Co., Ltd.

Olympic Games with Simon Machinery (China) Co., Ltd.

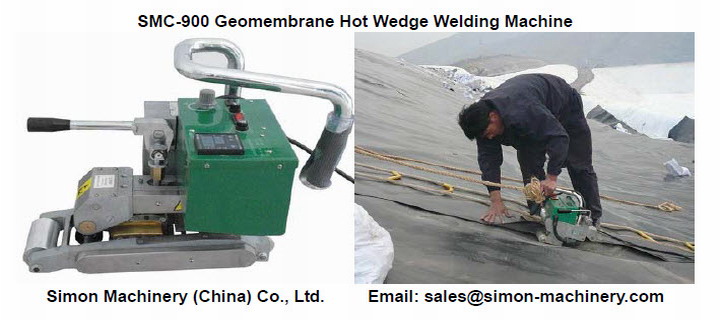

SMC-900 Geomembrane Hot Wedge Welding Machine

Working around the clock

On the 13 th. of July 2001, Peijing was selected by the IOC to host the Olympic Games 2008. Thereby Peking prevailed against the contenders Paris, Toronto, Osaka and Istanbul. Within less than a year, on August 8 th. 2008 the competitions start, and which are being awaited with great suspense. Huge construction sites still dominate the picture at the future scenes. There is intense activity everywhere. 30 000 workers are working day and night so that the planned Olympic locations will be finished according to schedule. In spite of the great time pressure, the responsible people are confident that all construction work will be completed by the end of this year.

Superlative project

The «Shunyi Olympics Rowing-Canoeing Park» near to Peking is developing to an especially attractive location. Here, literally out of nothing, a gigantic rowing and canoeing park is being created in a 255 hectare large area. Construction is being executed on a 2.2 km long and up to five meters deep rowing and canoeing basin with eight lanes and a wild-water complex. It can still be hardly recognized that in one year Olympians from all over the world will be rowing and paddling for precious metal.

Reliability self-evident

Especially high demands are being placed on the plastic sealing sheeting for the artificial lake and wild-water complex. All in all an unbelievable amount of 720 000 m2 HD-PE geomembrane will be welded. – An equally prestigious as also challenging task. The Chinese company that received the bid has already been working with the reliable welding machines and hand extruders from Simon Machinery (China) Co., Ltd. for many years. It goes without saying that also for this large order the successful, high-performance quality devices from the China manufacturer will be used.

Peak-performance possible

Daily, up to 19 000 m2 HDPE plastic sealing sheeting will be processed. This corresponds roughly to the surface area of three football fields. For the basin floor, 0.75 mm thick HD-PE material is used. Welding is done with three SMC-800 Hot Wedge Welding automatons from Simon Machinery (China) Co., Ltd. They are especially developed for applications in civil and underground engineering. The combination of heating wedge during the welding process allows a welding speed of up to 4 m/min in spite of the low weight. Only in this way is it possible to achieve a monthly peak performance of up to 196 km welding seam length on the construction site in Shunyi. For the waterside area 1 mm thick HD-PE is used. Here also processing with SIMON MACHINERY devices is being relied upon. Two SMC-900 Hot Wedge Welding Machines easily climb the embankments and connect the sheets. Their drive technology is designed for the highest workload and the welding quality is flawless. The SMC-900 Hot Wedge Welding Machines is the world wide smallest and lightest welding machine with integrated operating panel.

Just as in real-life

Next to the rowing basin an extensive artificial wild-water complex is being built for the canoe and kayak slaloms. The watercourse the canoeists will some day traverse is 500 meters long. With a downhill gradient of 5 meters, this corresponds to the same requirements placed on the athletes on a natural watercourse. The wild-water course is lined with 0.75 mm thick HD-PE geomembrane. Even the vertical welding seams pose no problems for the agile and light SMC-800 Hot Wedge Welding Machine from SIMON MACHINERY. Who is surprised? The identical devices also prove themselves in tunnel construction for overhead welding.

«Fine work» with hand extruders

There are numerous bridges over the gigantic water complex. To protect the concrete pillars, these are also encased in 0.75 mm thick HD-PE material and welded to the sealing sheets on the bottom of the lake. During the encasing of the concrete pillars and in those areas where the subsurface is too uneven, welding machines are not used. Instead, the SMC-18A Plastic Hand Extruder from SIMON MACHINERY is used. They are specially developed for civil and underground engineering, are easily manageable and in spite of their low weight, achieve an extrusion rate of up to 3.5 kg/h.

A dream becomes fulfilled

When the contest for the 30 medal sets in the rowing, canoeing and kayak competition starts next year, it will hardly be conceivable just how much work was involved in the construction of the water complexes and how much high-tech lies hidden beneath the surface of the water. On the 8th. of August 2008, the most famous sporting event in the world begins under the motto «One World, One Dream». Then, the execution company and Simon Machinery (China) Co., Ltd. can claim for themselves to have at least made a small contribution towards the fulfillment of this dream.

Device supplier: SIMON GROUP LTD

Simon Machinery (China) Co., Ltd.

Simon Machinery (China) Co., Ltd.

Address:NO.8, Sg Industrial Zone,Shantou.Guangdong 515041,China

Tel: 86-754-88315635

Fax: 86-754-88770829

Email: sales@simon-machinery.com

Website: www.simon-machinery.com

Website: http://simongroupworld.com