Artificial lagoons in Chile – a landscape of superlatives

World record with SIMON MACHINERY

Crystal Lagoons Corp.’s concept and technology enable to build crystal clear water bodies in almost unlimited dimensions thanks to its uniquely new and patented concept. In a region where the sea is too rough and thus unattractive to tourists, it is now possible to construct giant artificial lagoon landscapes. There are already several of these pools in the world. One of them is situated in Las Brisas de Santo Domingo, Chile. But the world’s largest one can be found in San Alfonso de Mar. It covers an area of 8 ha. In fact, Crystal Lagoonsa Corp. managed an entry in the Guinness Book of Records with it in 2007. The longest distance stretches for more than 1 km. You can actually see it on “Google Earth”. An even bigger basin with an impressive 12.5 ha area of crystalline water is currently taking shape in the Egyptian resort of Sharm El Sheikh.

Cost-effective maintenance

To ensure the quality of these huge bodies of water at the lowest expense, Crystal Lagoons Corp. has developed an innovative technology patented in 150 countries. It is based on an energy-saving filter system combined with a pulsed flushing method for disinfecting the water. That means up to 100 times less chemicals and 50 times less energy are used during the cleaning than with conventional methods.

Las Brisas de Santo Domingo – a challenging project

Construction of this 2.2 ha complex with a maximum length of 320 meters and 70 meters width was a challenge in itself. The substrate had to be sloping so that the lagoon andscape offers different depths for the various types of water sports. The ground was sandy, which made welding work considerably difficult. And what is more, a tight construction time of only four months had to be met.

The perfect sealing system

The entire structure consists of a geotextile overlapping on the sandy substrate of the excavation. A 0.75 mm thick HDPE plastic sealing sheeting was then laid directly on the geotextile. The LLDPE sealing, especially designed in the US under Crystal Lagoons’ brand and specifications, and exclusively offered to their clients, completed the structure. 5400 m weld seams had to be processed for every position. A total of 16.2 km were therefore welded. All the requirements for tightness and aesthetics are fulfilled with this system.

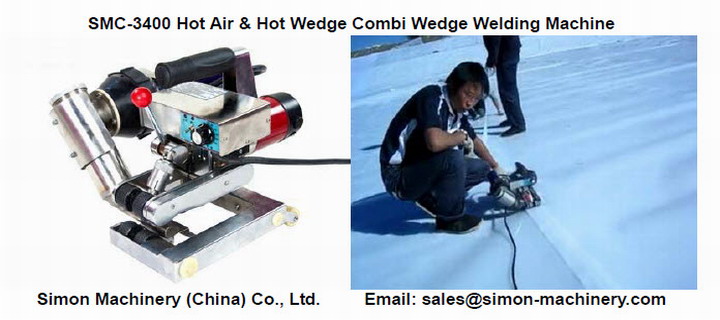

SMC-3400 Welding machines from SIMON MACHINERY busy at work

Two combi-wedge welding machines SMC-3400 Hot Air & Hot Wedge Combi Wedge Welding Machine made by SMON MACHINERY were used for the welding work. The welding process using the SMC-3400 Hot Air & Hot Wedge Combi Wedge Welding Machine involves an air heated hot wedge. This lightweight welding machine proven in use throughout the world is compact and easy to handle, yet impressively powerful. Even thin plastic sealing sheets like those used here can be handled by the SMC-3400 Automatic Hot Air & Hot Wedge Combi Wedge Welding Machine with an astonishing speed of up to 6 m/min.

SMC-18A Hand Extruder & SMC-1600, the right tools for any challenge

Connections and detail work were carried out with the reliable manual welding device SMC-1600 Hot Air Gun. It was no problem to weld seams in positions less suitable for welding machines thanks to the long-shaped SMC-18A Plastic Hand Extruder. This hand extruder allows you to work in an upright position without strain. The SMC-18A Plastic Hand Extruder really shows its merit when welding batches with thick materials.

Guaranteed quality with SMC-910 Manometer

The proven test instrument SMC-910 Manometer made it possible to check the weld samples without complications directly on the construction site. The SMC-910 Manometer lets you test peel, tensile and shear forces. If need be, the relevant parameters for speed, temperature and pressure can be adjusted afterwards on the welding machine.

A successful finish

Hard to believe: The San Alfonso de Mar project was able to be completed successfully within just 120 days. This was thanks to the collaboration between experienced engineers and the layout company Termofusion Siplas Ltda, who have been relying on the powerful, world-proven welding equipment from SIMON MACHINERY for many years. “We work almost exclusively with SIMON MACHINERY tools. Both the welding quality, as well as the speed and reliability of the SIMON MACHINERY devices never cease to amaze us”, is how Waldo Neira, Project Manager of Termofusion Siplas Ltda, praises the equipment from SIMON MACHINERY.

The finished lagoon in Las Brisas de Santo Domingo, Chile.

Welding work: Termofusion Siplas Ltda

Material: HDPE 0.75 mm

Device supplier: SIMON GROUP LTD

Simon Machinery (China) Co., Ltd.

Simon Machinery (China) Co., Ltd.

Address:NO.8, Sg Industrial Zone,Shantou.Guangdong 515041,China

Tel: 86-754-88315635

Fax: 86-754-88770829

Email: sales@simon-machinery.com

Website: www.simon-machinery.com

Website: http://simongroupworld.com